Advantages of Helical-Hypoid Gear Reducers in Industrial Applications

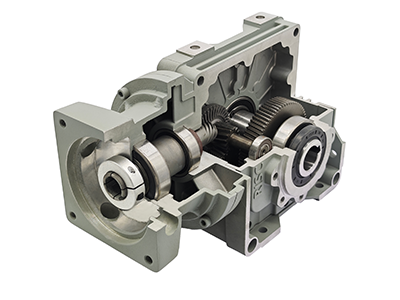

The Helical-Hypoid Gear Reducer has become a preferred choice in many industrial sectors due to its high torque density, energy efficiency, and compact structure. Compared to conventional gear drives, it offers smoother transmission and better adaptability for heavy-duty operations.

1. High Torque and Load Capacity

Thanks to the unique hypoid gear design, these reducers deliver higher torque output with reduced gear wear. This makes them ideal for heavy-duty gear reducer applications in conveyor systems, material handling, and packaging machinery.

2. Compact and Space-Saving Design

The compact gear drive design helps reduce installation space without compromising performance. Industries with limited machine footprint, such as food processing and textile production, benefit greatly from this feature.

3. Energy Efficiency and Durability

With optimized meshing and lower friction losses, the energy-efficient speed reducer significantly improves operational cost savings. Its long service life also reduces maintenance downtime, ensuring continuous production.

4. Wide Range of Industrial Applications

Helical-Hypoid Gear Reducers are widely used in automation systems, robotics, transport equipment, and industrial conveyors, making them a versatile solution for modern engineering needs.

Conclusion

For businesses seeking reliability, efficiency, and high performance, the Helical-Hypoid Gear Reducer is a smart investment. Its superior load capacity and long-term energy savings make it a top choice across multiple industries.

Leave A Reply

Your email address will not be published. Required fiels are marked